Quality Assurance

Our quality assurance department is involved with every aspect of the process starting from the incoming material to the finished part.

All production material is chemically certified. Then our quality checks start with a first piece inspection to assure proper setup, then in-process inspection to verify process capability and last, a final inspection. All of the above processes are properly documented.

We utilize several types of inspection equipment such as:

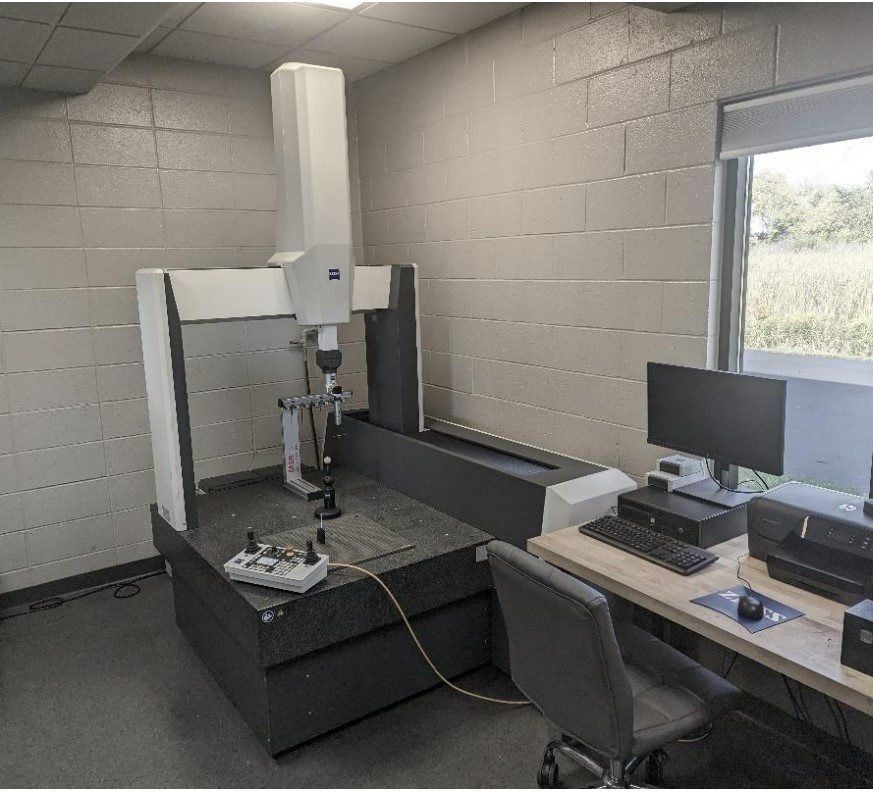

Ziess CMM 26” x 24” x 17” manual

Ziess CMM CALYPSO 27” x 39” x 22” fully automatic

Hexagon Metrology CMM ROAMER

Leco micro hardness checker

Rockwell-wilson twin hardness tester

Taylor Hopson surface tester

2019 Ziess Calypso CMM